| Control system | Mitsubishi PLC control, 7-inch color touch screen operation |

| Drive mode | Motor + precision screw guide rail forming transmission mechanism |

| Test station | Single station |

| Test items | 1. Bending test 2. Torsion test 3. Tensile test 4. Tail tensile test |

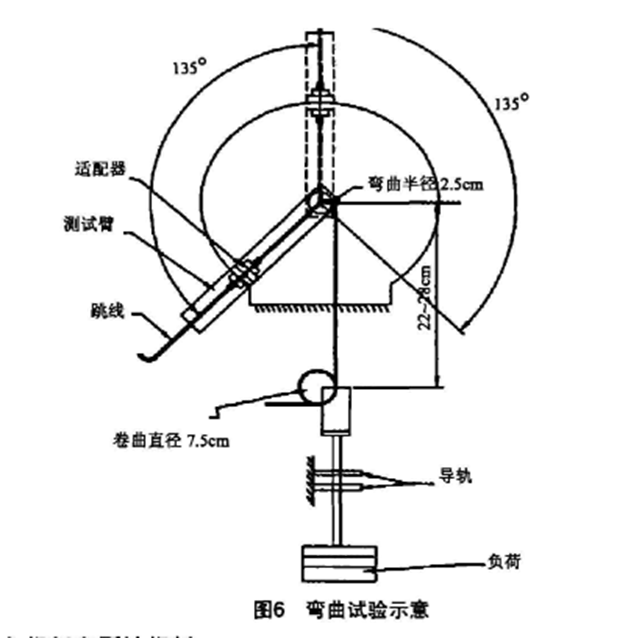

| Main technical parameters of bending test |

| Sample | Optical fiber cable movable connector |

| Sample clamping method | Mechanically clamped to a special fixture, the clamping point

position is adjustable

|

| Bending angle | 0-360° adjustable (can be preset to ±30°, ±45°, ±60°, ±90°) |

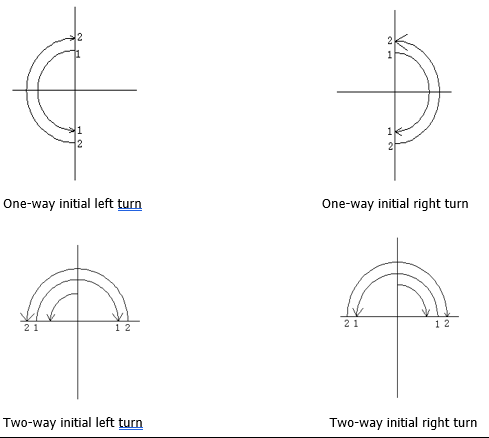

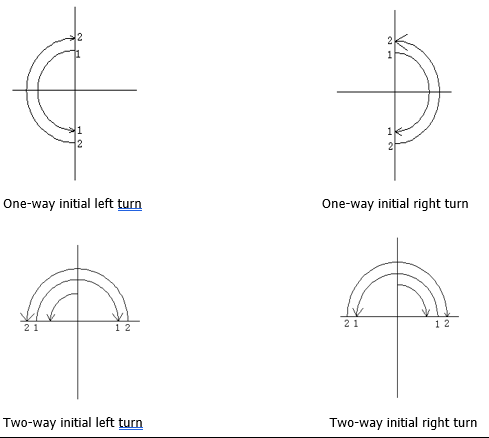

| Bending direction selection |

|

| Bending rate | 0-60 times/min, touch screen preset |

| Bending times | 0~999999 can be preset, the default is 100 times |

| Load weight | 0.6kg, 0.9kg |

| Insertion and return wear and tear | External testing |

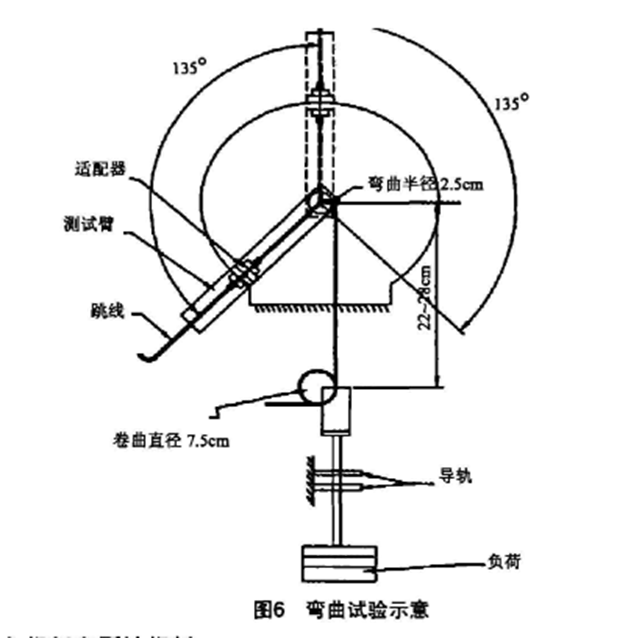

| Main technical parameters of torsion test |

| Sample | Optical cable type optical fiber movable connector, coated optical

fiber type, bare optical fiber type |

| Sample clamping method | Mechanically clamp it to the special fixture according to Figure 6,

the clamping point position is adjustable |

| Direction of rotation | Forward and reverse rotation can be selected (can be preset to

rotate forward n times and then reverse n times) |

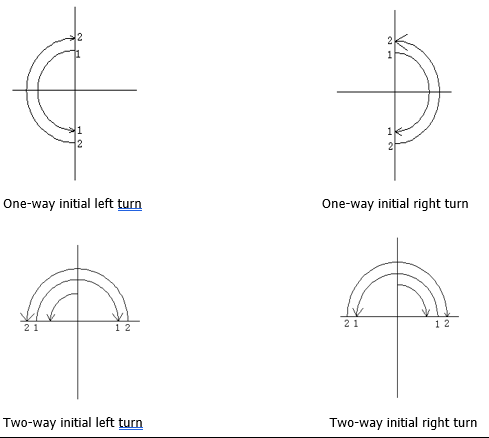

| Bending direction selection |

|

| Rotation rate | 0-10r/min, touch screen preset |

| Number of rotations | 0~9999.9 can be preset, the default is 9 times |

| Selection table for number of specimen rotation turns | | Table 2 Winch rotation requirements | | Tail type | Clockwise rotation (circle) | Counterclockwise rotation (circle) | | Optical cable type | 2.5 | 5 | | Optical fiber type | 1.5 | 3 |

|

| Load weight | 0.5kg, 0.75kg, 1.35kg |

| Insertion and return wear and tear | External testing |

| Main technical parameters of tensile test |

| Sample | Optical fiber cable movable connector |

| Sample clamping method | Mechanically clamp it to the special fixture according to Figure 6,

the clamping point position is adjustable |

| Rotational position | 0° (straight pull), 90° (side pull), automatic switching |

| Force application method | The motor controls the lifting and lowering of the pallet to lift

and release the weights to achieve the purpose of applying pulling

force. |

| Force application time | 0-9999S, touch screen setting |

| Load weight | 1.5kg, 2.3kg, 3.4kg 4.5kg, 6.8kg, superimposed combination to

achieve |

| Insertion and return wear and tear | External testing |

| Main technical parameters of tail tensile test |

| Sample | Optical cable type optical fiber movable connector, coated optical

fiber type, bare optical fiber type |

| Sample clamping method | Mechanically clamp it to the special fixture according to Figure 6,

the clamping point position is adjustable |

| Rotational position | 0°, 90°, 135° automatic switching |

| Rotation rate | 0-10r/min, touch screen preset |

| Direction of rotation | Swing in sequence from 0° to 90° to 135° |

| Load weight | 0.25kg, 0.5kg, 0.7kg, 1.5kg, 2.0kg 4.5kg, 6.8kg, superimposed

combination to achieve |

| Sample load selection table | | Table 3 Load requirement | | Load | 0° | 90° | 135° | | Optical cable type | | 0.25kg | √ | √ | √ | | 0.7kg | √ | √ | - | | 1.5kg | √ | √ | - | | 2.0kg | √ | √ | - | | Φ0.9mm Coated Fiber Type | | √ | √ | √ | | √ | √ | - | | Φ0.25mm Bare fiber type | | √ | √ | - | | √ | √ | - | | Note: √ Indicates the test to be conducted |

|

| Insertion and return wear and tear | External testing |