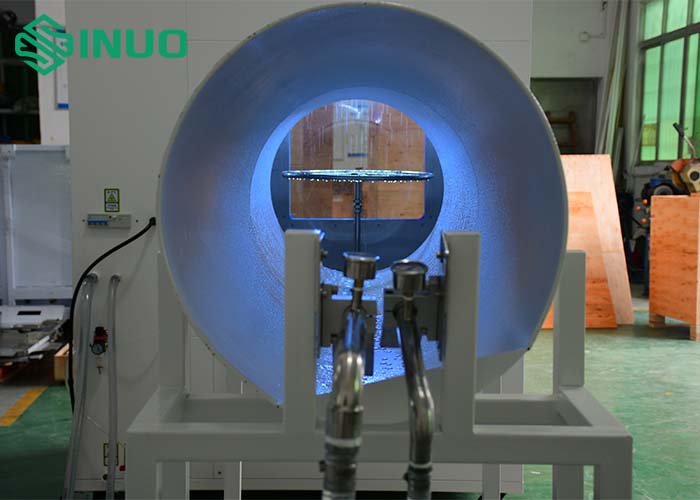

IEC 60529 All in One Integrated Waterproof Test Chamber for

IPX1~IPX6 Tests 1000L

Product Overview

The IPX1~IPX6 Water Ingress Test Chamber is a highly reliable and

versatile solution designed to evaluate the waterproof performance

of a wide range of electrical and electronic products. From gentle

dripping to powerful water jets, this all-in-one system supports

comprehensive testing from IPX1 to IPX6, strictly following

IEC60529:1989 +A1:1999 +A2:2013 standards (including Figures 4 and

6).

Whether you're testing outdoor lighting, home appliances,

automotive components, or electrical enclosures, this chamber

ensures that your products withstand real-world rain, splash, and

jet water exposure. It helps you detect design flaws early,

minimize risks, and improve product reliability before market

release.

Features:

✅ Covers IPX1 to IPX6 in one chamber for full waterproof compliance

testing

✅ Built to IEC60529 standard, ensuring precise and repeatable test

results

✅ Ideal for multiple industries: electronics, automotive, lighting,

appliances

✅ Supports R&D, design validation, and factory inspections

✅ Reduces failure risks like corrosion, short circuits, and

deformation

✅ Engineered for durability and ease of use in lab and production

environments

Perfect for manufacturers, testing labs, and quality assurance

teams, this chamber is an essential tool for improving product

durability and safety in harsh environments.

✅ IPX56: Configured a spray nozzle according to the specifications of

IEC60529 figure 6 (as shown below):

✅ Turntable drive: use high-quality stepper motor, can automatically

control the positive and negative rotation (forward and reverse:

suitable for the sample power-on test and to prevent cable

winding).

✅ The test time can be set on the touch screen. The setting range is

0-999min (adjustable).

✅ The core control system adopts 7-inch touch screen + PLC. The

electrical components adopt imported brands such as Omron. The

wiring process conforms to the requirements of national standards.

The layout of the electric board is reasonable, the wiring is firm

and the marking is clear.

✅ There is configured with a waterproof socket inside the chamber for

power on the sample.

✅ With safety protections of leakage protection, water shortage

protection, short circuit protection.

Technical Parameters:

| Technical Parameters | Basic Parameters |

| Inner Chamber Size | L1000*W1000*H1000mm |

| Outer Chamber Size | L1480*W3800*H1800mm |

| Turntable Diameter | ¢400mm |

| Turntable Maximum Load Bearing | 10KG |

| Turntable Speed | 1-5r/min (adjustable) |

| Turntable Rotation Method | Always positive / positive and negative alternate |

| Flow Adjustment Method | Manually adjust flow by adjusting flow meter on the panel |

| Test Time | 0-999 min |

| Power supply for sample | Configured with a waterproof socket inside the chamber for client

to power on sample during test

|

| Equipment dimensions | Approx.2770mm(L)*1330mm(W)*1750mm(H) |

| Total Weight | Approx. 350kg |

| Required site place | 3.2m(L)*2m(W)*2m(H) |

| IPX12 Dripping Testing Parameters |

| Drip area | 600*600mm |

| IPX12 nozzle size | Diameter 0.4mm |

| Distance between drip holes | 20*20 mm |

| Water flow | IPX1=1mm/min; IPX2=3mm/min |

| Drip board lifting method | Not lifting (fixed) |

| IPX34 Oscillating Tubes Parameters |

| Oscillation Tube | R200 mm and R400mm |

| Distance between Nozzle Sample | Within 200mm |

| Spray Aperture Spacing | 50 mm |

| Oscillating Tube Swing Angle | ±60° (IPX3), approximately ±160°(IPX4) (Note: standard requires IPX3:120°; IPX4: almost 360°, but due to

there is turntable under oscillating tube during test, so 360° can

not achieved during actual testing, if without turntable, then 360°

can be achieved) |

| Angle Between Two Holes | 120°(IP3) 180°(IP4) |

| Needle Hole | φ0 .4 mm |

| Oscillating Speed | IPX3: 15times/min; IPX4: 5times/min |

| Water Flow of Each Hole | 0.07 L/min +5% |

| Spray Pressure | 80-150Kpa |

| IPX34 Spray Nozzle Parameters |

| Parameters of Spray Nozzle | Outer diameter: Ф102mm, spherical diameter: SФ75.5mm, 1 hole at the

center, 2 inner circles of 12 holes at 30° pitch,4 outer circles of

24 holes at 15° pitch, total 121 holes of Ф0.5mm, made of brass. |

| Water Flow | 10L/min±5% adjustable by flow meter (flow meter is not included in

this item, should be prepared by user) |

| Pressure | 50~150Kpa, the pressure gauge measuring range: 0~0.25Mpa |

| Moving Shield | Made of aluminum, can be detachable Note: the aluminum moving shield is easy to deform, pay attention

during use |

| IPX56 Jet Nozzle Parameters |

| IPX5 Nozzle Jet Aperture | 6.3mm |

| IPX6 Nozzle Jet Aperture | 12.5mm |

| IPX5Jet Flow | 12.5±0.625 |

| IPX6 Jet Flow | 100±5L/min |

| Water Pressure (Mpa) | Adjusted according to the specified water flow |

| Jet Distance | 2.5M (nozzle away from the center of the turntable) |

| Nozzle Fixed Method | Mechanical fixing |

| Electrical Parameters |

| Power Supply for Equipment | 380V, 50Hz |

| Equipment Power | 3.0KW |

| Safety Protection Function | Leakage protection, water shortage protection, short circuit protection |

| Conditions of Use | The following conditions are guaranteed by the user and the

corresponding connection is completed. |

| Use of Space | The ground is level, the drainage is smooth, floor and wall are

waterproofing, Ground bearing capacity is not less than 200kg/㎡ Well ventilated No strong vibration around the device No strong electromagnetic field around the device No flammable, explosive, corrosive substances and dust around the

equipment Appropriate use and maintenance space is left around the equipment: Rear side, left and right side, top of the equipment: 800mm; front

side of equipment: 1400mm |

| Environmental Conditions | Temperature:5℃~35℃ Relative humidity: ≤85% Air pressure:86kPa~106kPa |

| Power Supply Conditions |

| Voltage, Frequency | AC380V±10%; 50Hz±10%; three-phase four-wire + protective ground

wire |

| Power | 3.0kW |

| Protective Grounding Resistance | Grounding resistance of protective grounding wire is less than 4Ω |

| Power Switch | 1. The user is required to configure the leakage protection air

switch of the corresponding capacity for the equipment at the

installation site, and the switch must be used independently for

the device. 2. It is forbidden to use the knife switch or power socket. 3. The leakage protection air switch is not more than 2 meters away

from the equipment. |

| Water Source | 1. The user is required to configure the water source for the

equipment at the installation site, the water pressure is not less

than 0.2Mpa, and the 4-point faucet is installed. 2. The position of the faucet is no more than 2 meters away from

the equipment. |