Volume, dimensions, and weight |

Volume | 800L |

Inner chamber dimensions | W1000mm×H1000mm×D800mm |

Outer chamber dimensions | W1250mm×H2170mm×D2250mm |

Weight | 1400 kg |

Performance |

Test environment conditions | When there is no sample in the test chamber, the ambient

temperature is +25°C and the relative humidity is ≤85%. |

Test methods | GB/T 5170.2-2008 Temperature test equipment GB/T 5170.5-2008 Damp heat test equipment |

Temperature range | -70℃~180℃ |

Temperature fluctuation | ≤1.0℃ |

Temperature uniformity | ≤2.0℃ |

Temperature deviation | ≤2.0℃ |

Heating rate | -60℃→+150℃ 15℃/min (average over the whole process) |

Cooling rate | +150℃→-60℃ 15℃/min (average over the whole process) |

Load | 50KG |

Humidity range

| (10~98) %RH (refer to the temperature and humidity controllable

range chart, no active heat load)

|

Relative humidity deviation

| ±3.0%RH (when humidity>75%RH) ±5.0%RH (when humidity ≤75%RH) |

Meet test standards | GB/T5170.2-2008 Temperature test equipment GB/T5170.5-2008 Damp heat test equipment GB/T2423.1-2008(IEC60068-2-1:2007) Low temperature test method Ab GB/T2423.2-2008(IEC60068-2-2:2007) High temperature test method Bb GB/T2423.3-2006(IEC60068-2-78:2007) Constant damp heat test method

Cab |

Structural characteristics |

Insulation envelope structure | Outer wall material: high-grade cold-rolled steel plate, surface

spray treatment (FQY standard color) Inner wall material: stainless steel plate SUS304 Box insulation material: rigid polyurethane foam + fiberglass Door insulation material: fiberglass |

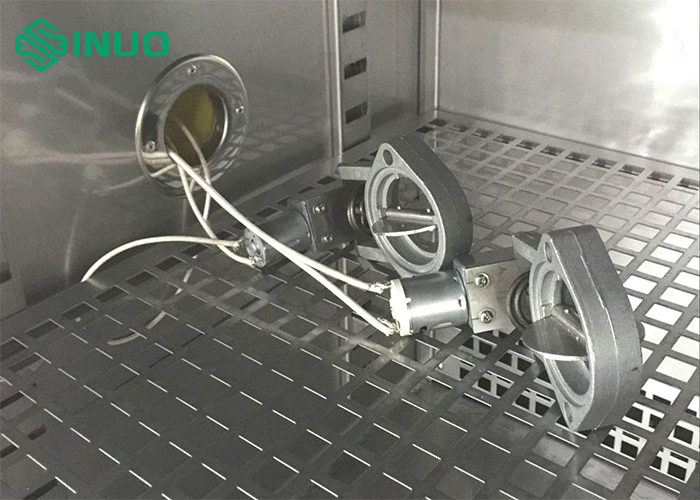

Air conditioning channel | Centrifugal fans: 4, AC380V 550W Heater, evaporator (also dehumidifier), water supply and drainage

outlet, dry bulb temperature sensor, humidifier, dry burn

preventer, electronic humidity temperature sensor, wet bulb water

tank

|

Standard configuration of test chamber | Observation window: 1 piece of transparent electric heating film

hollow tempered glass (located on the door), visual range is about

500mm×600mm Lighting: 11W/AC220V 1 piece Mobile casters: 4 pieces Sample rack: 2 layers of stainless steel sample rack, load-bearing

(evenly distributed): 50kg/layer |

Lead hole | There are 2 test lead holes on both sides of the box (1 on each

side), and the test lead holes are equipped with 4 soft plugs in

total |

Door

| Single hinged door (left hinge, right handle), equipped with

observation window, lighting, window frame/door frame

anti-condensation electric heating device |

Control panel | Controller display, over-temperature protection setter, USB

interface, fault light |

Mechanical room | Refrigeration unit, drain pan, drain hole |

Power distribution control cabinet | Distribution boards, distribution panels, exhaust fans |

Heater | Nickel chromium alloy electric wire heater Heater control mode: contactless equal period pulse width

modulation, SSR (Solid State Relay) Heater power: 6kW×3 |

Humidifier

| Shallow water tray humidification method humidification method Stainless steel armored heater Heater control mode: contactless equal period pulse width

modulation, SSR (Solid State Relay) Water level control device, heater anti-dry device Humidifier power: 6KW×3 |

Water source | Humidification water supply system |

Power cord hole and drainage hole | Located on the back of the box |

Refrigeration system |

Working method | Mechanical compression binary cascade refrigeration method |

Cooling method | Water cooling |

Refrigeration compressor | Semi-hermetic low-noise piston compressor |

Evaporator | Fin tube heat exchanger (also used as dehumidifier) |

Condenser | Shell and tube heat exchanger/casing heat exchanger |

Throttle device | Thermal expansion valve, capillary tube |

Evaporative condenser | Stainless steel brazed plate heat exchanger |

Refrigerator control method | The PLC (Programmable Logic Controller) of the control system

automatically adjusts the operating conditions of the refrigerator

according to the test conditions. Evaporator pressure regulating valve (to prevent evaporator

freezing). Compressor return air cooling circuit. |

Environmentally friendly refrigerant | R404a/R23 (ozone depletion index is 0) |

Electrical control system | |

Controller model | TEMI 2700 |

| Function introduction | The controller system mainly consists of 2 parts. That is, the LCD

control panel and the input/output control board (I/O board). The

LCD controller displays the cause and solution of the fault in

Chinese characters based on the alarm signal transmitted through

communication to the I/O board. Users can choose between English

menu and Chinese menu according to their needs. LCD controller has

built-in lithium battery and calendar clock. It has the functions

of power outage protection and scheduled power on/off. |

| Monitor | 7.0-inch 640×480 dot matrix, TFT color LCD display |

| Operation mode | Program mode, fixed value mode |

| Setting method | English menu, touch screen input |

| Program capacity | Editable: 20 programs. Each program has a maximum of 50 steps and

can be set to 20 cycles (each cycle step has a maximum of 9999

cycles) Fixed: 10 procedures The program can be linked to achieve unlimited operation. |

| Setting range | Temperature: Adjust according to the temperature working range of

the equipment (upper limit +5℃, lower limit -5℃) Humidity: (0~100)%RH (temperature and humidity test equipment) |

| Resolution | Temperature: 0.1℃; Time: 0.1min; Humidity: 0.1%RH (temperature and

humidity test equipment) |

| Input | Thermocouple (platinum resistance/voltage/current, etc., according

to equipment needs) |

| Communication function | RS-485 interface, with local and remote communication functions

(needs to be equipped with centralized monitoring software,

RS-485/RS-232 converter, and needs to occupy one COM port and one

USB port of the PC). Up to 16 devices can be connected at the same

time, with a maximum cumulative cable length of 800m. PC software usage environment: IBM PC compatible machine, PⅡ or

above CPU, 128M or above memory, English Windows2000 or English

WindowsXP operating system. |

| Control method | Anti-integral windup PID BTC balance temperature control method (temperature test equipment) BTHC balanced temperature and humidity control method (temperature

and humidity test equipment) |

| Curve recording function | It has SRAM with battery protection, which can save the device's

setting value, sampling value and sampling time. You can touch the

screen with your finger to slide and observe the data in real time. The default maximum storage time is 60 days (when the sampling

period is 1.5min). The sampling period can be set by the user. The

sampling time calculation formula is as follows: If the sampling period is set to t min, the storage time:

d=((65536xt)/60)/24 (days) |

| Test data collection | 1. Screen interface curve output---directly save the curve

interface on the touch screen or any interface required by the

customer as a *.bmp picture to a U disk or directly use a printer

to print the curve interface on the touch screen or customer

requirements (interface software needs to be changed) any

interface. 2. USB function---equipped with 1 8G U disk. During the test,

insert the U disk into the USB interface of the controller, and the

test data will be automatically recorded into the U disk and saved

as a *.csv data file (not a graph). The sampling period can be set

on the screen. It can be opened and processed using EXCEL and other

software. 3. Connect to the printer (optional): --- Configure the printer to

print the test date, set temperature, measured temperature, set

humidity, and measured humidity by setting the number of prints

according to time. 4. Connected to PC (optional): ----Through the centralized

monitoring software, test data can be recorded, automatically

displayed as a curve in the PC, and can be printed directly, with

no limit to the recording time. File size depends on hard drive

capacity. The PC can also be used as an operating terminal to

achieve remote monitoring. |

| Input/output control panel (I/O panel) | Input characteristics: 24 photoelectrically isolated 24V switching inputs. The I/O board

periodically scans 24 switches to understand the real-time

operating status of the equipment and the status of the equipment

protection device. 5 analog photoelectrically isolated input

channels. The analog channel can be connected to K and T-type

thermocouples, Pt100 platinum resistance, 0~10V DC voltage source,

0~20mA, 4~20mA current source input. Output characteristics: 20 relay outputs with photoelectric isolation. (Soil: 24VDC,

Contact: 5A, 250VAC, 5A, 30VDC). 4 transistor outputs with

photoelectric isolation. It can directly drive the solid state

relay with 24VDC as the control end. The temperature and humidity

recorder can be used by connecting a third-party manufacturer's D/A

module (standard DC 4~20mA output) to the RS-485 bus that

communicates with the LCD controller. Programmable logic control: The I/O board has built-in programmable logic control and has the

functions of a PLC. This makes the I/O board more powerful than an

ordinary pure input/output board, making it easy and convenient to

change the logic control method and expand the I/O board. The

program can be flexibly changed according to the user's special

requirements through the PC, downloaded and solidified on the I/O

board. Communication function: The I/O board has an isolated RS-485 communication interface.

Through this communication interface, the I/O board sends analog

and switching input and output values to the LCD control panel for

calculation and display. And accept control commands from the LCD

control panel. |

| Additional features | Fault alarm and cause, processing prompt function. Power failure

protection function. Upper and lower limit temperature protection

functions. Timing function (automatic start and automatic stop),

self-diagnosis function. |

Temperature and humidity measurement | Temperature: Armored T-type thermocouple or PT100 Humidity: Classic wet and dry bulb thermometer method (damp heat

type) |