Sinuo is an innovation manufacturing company, specializing in the

research and development and sales of laboratory construction and

testing equipment for electrical appliances (covering the

construction of energy efficiency and performance laboratories, as

well as supplementary waterproof testing laboratories, materials

flame-retardant laboratories, basic general testing equipment,

etc.), Sinuo aims to provide clients with complete laboratory

construction, system integration, R&D, rectification and

after-sales service, and strive to be the leader of one-stop

service for laboratory construction in the field of electrical

appliance testing.

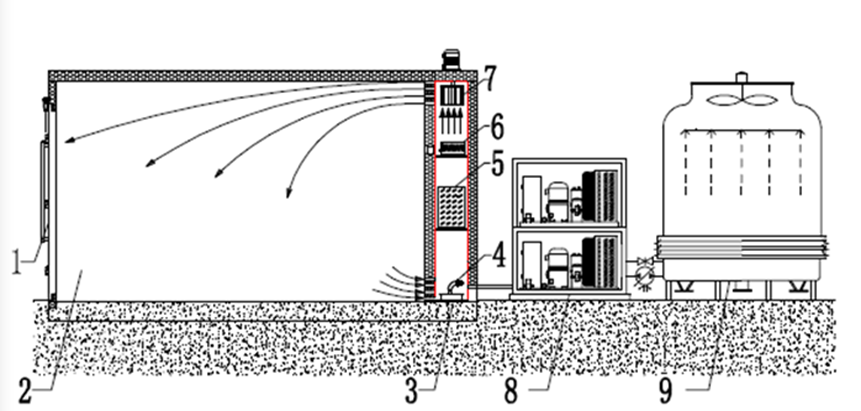

Sinuo products are composed of all kinds of testing

equipments as per standards of IEC/ BS/ EN/VDE/UL/ ISO...,

such as household appliances testing equipment, energy efficient

testing laboratories and comprehensive performance test system for

household appliances, battery testing

equipment, automotive testing equipment, luminaries

testing equipment,IP code testing equipment, environmental test

chamber, flammability test chambers, EMC testing equipment and etc.

Sinuo employees include a highly trained staff of engineers for

sales and service, that are committed to offer satisfactory

products and prompt service to all home and abroad customers.

Sinuo cooperate with many research institutions and schools to

enable our techincal capacities. Sinuo has two own factories, one

is in Guangzhou, the other is in Dongguan, and authorized agents

and representative offices in Korea, South Africa, Egypt,Pakistan

and Philippines.

Sinuo combines all the R/D and production advantages, contributes

to provide perfect, high-end and systematic electrical appliance

testing laboratory solutions, products and services for corporate

customers, universities and third-party laboratories. Our clients

include Bureau Veritas, CSA, Intertek, TUV Rehiland, TUV SUD, SGS, etc.